Imagine counting your entire inventory in minutes instead of days. That’s not a sci-fi fantasy; it's the core promise of using RFID for tracking assets. This technology is like an automated, digital roll call for your stuff, letting you identify and locate hundreds of items at once without even needing to see them.

How RFID Transforms Asset Tracking

Think about the old way of doing inventory. It's usually one person with a clipboard or a barcode scanner, meticulously zapping each item, one by one. The whole process is painfully slow and notoriously prone to human error. Just one missed item or a misread barcode can throw everything off, leading to delays, financial loss, or the simple frustration of not finding what you need. That manual approach just doesn't cut it anymore.

RFID (Radio Frequency Identification) flips the script entirely. It ditches the slow, one-at-a-time scan for a lightning-fast, bulk-reading capability. Instead of hunting for a barcode, an RFID reader sends out radio waves that power up and talk to smart tags attached to your assets. These tags then broadcast their unique ID numbers back to the reader, and poof, your inventory check is done in a flash.

The Three Core Components

An RFID system is really a team of three key players, and understanding their roles is the first step to seeing how powerful this tech can be.

The components themselves are pretty straightforward, but together, they create a seamless ecosystem for managing your physical world.

The Core Components of an RFID Tracking System

| Component | Function | Analogy |

|---|---|---|

| RFID Tags | Smart labels with a microchip and antenna that store a unique ID. They're the voice for each of your items. | A unique name tag for every single item you own |

| RFID Readers | Devices (handheld or fixed) that send out radio waves to "wake up" the tags and listen for their responses. | The ears of the system, listening for the names |

| Software | The brain that processes the raw data from the readers and turns it into useful information (what you have, where it is). | The translator that makes sense of the conversation |

This combination allows someone with a handheld reader to simply walk through a room and instantly capture data from every tagged item, even if they’re hidden inside boxes or tucked away in cabinets.

An RFID system eliminates the need for line-of-sight scanning, which is the single biggest limitation of barcodes. This capability alone can slash inventory counting times by over 90% in many environments, turning a multi-day chore into a job that takes just a few hours.

The demand for this kind of efficiency is exploding. The global RFID market is expected to jump from USD 12.61 billion in 2025 to USD 25.24 billion by 2033, growing at a 9.1% clip each year. What's driving this? A massive need for better, smarter inventory management across practically every industry.

By automating how you collect data, RFID for tracking assets doesn't just make you faster; it delivers a level of accuracy that manual methods can only dream of, setting a new standard for knowing what you have and where it is. To see how this data comes to life, our guide on effective asset location tracking offers a deeper look into visualizing and using this information.

Choosing the Right RFID Tags and Readers

Getting started with RFID for tracking assets hinges on one critical decision: picking the right hardware. The tags and readers you choose will dictate your system's range, reliability, and cost. It sounds intimidating, but once you understand the key differences, the right choice becomes much clearer.

Think of it this way: are you trying to monitor a few high-value pieces of equipment across a massive warehouse, or are you just trying to keep tabs on hundreds of small items in a single room? Each job needs a different tool, and matching the hardware to your specific goal is the secret to success.

This decision tree gives you a quick visual on when RFID starts to make more sense than simpler methods like scanning barcodes one by one.

As the graphic shows, if scanning items individually is creating a bottleneck, the bulk-reading power of RFID is the logical next step to boost your efficiency.

Decoding the Different Types of RFID Tags

Your first big decision is about the tags themselves. RFID tags come in three main flavors, and each one has its own power source, read range, and price point.

A Comparison of RFID Tag Types for Asset Tracking

To help you choose the right type for your needs, here's a quick breakdown of passive, active, and semi-passive tags. This table lays out the key differences so you can see at a glance which one fits your project.

| Tag Type | Power Source | Typical Read Range | Cost per Tag | Best Use Case |

|---|---|---|---|---|

| Passive | Powered by reader's radio waves | A few inches to 30 feet | $0.10 – $0.50 | High-volume, short-range tracking like retail inventory or tool management. |

| Active | Internal battery | 300+ feet | $20 – $100+ | Long-range tracking of high-value assets like shipping containers or vehicles. |

| Semi-Passive | Small internal battery | Up to 100 feet | $1 – $10 | Monitoring sensitive items that need more range, like in cold-chain logistics. |

Ultimately, your choice will balance cost, range, and the value of the assets you're tracking. Passive tags are perfect for volume, while active tags are the go-to for valuable, mobile assets.

Breaking Down the Tag Types

1. Passive RFID Tags

These are the most common and cheapest tags you'll find. They don’t have a battery. Instead, they wake up and get their power directly from the radio waves sent out by an RFID reader.

- How They Work: Imagine a passive tag is like a mirror. When the reader shines a signal (the "light"), the tag uses that energy to power its chip and reflect its unique ID back. It's an elegant and simple system.

- Best For: High-volume applications where cost is a major factor and items are scanned up close. Think library books, retail inventory checks, or organizing tools in a workshop.

2. Active RFID Tags

Active tags are the powerhouses of the RFID world. They have their own battery, which lets them broadcast their signal over seriously long distances.

- How They Work: Instead of waiting for a reader's signal, an active tag acts like a tiny beacon, constantly transmitting its own signal. This allows it to be picked up from much farther away.

- Best For: Tracking high-value, mobile assets across large areas. This is the tech used to monitor shipping containers in a port, find specific vehicles in a giant lot, or keep an eye on critical equipment at a construction site.

3. Semi-Passive Tags

Also known as battery-assisted passive (BAP) tags, these are a smart hybrid of the other two types. They use a small battery to power the tag's internal chip but still rely on the reader’s signal to send their data.

- How They Work: The battery keeps the tag's chip or sensors "on" and ready, which boosts its performance and read range well beyond a standard passive tag. But it doesn't broadcast constantly, saving battery life and cost compared to a fully active tag.

- Best For: Situations that need more range and reliability than a passive tag can deliver, like monitoring temperature-sensitive goods during shipment.

Selecting the Right RFID Reader

Once you’ve got a tag type in mind, you need a reader to communicate with them. Readers are the brains of the operation, and they come in two main forms.

Fixed RFID Readers

These readers are installed in key locations, like doorways, conveyor belts, or other chokepoints. They create an "always-on" monitoring zone that works automatically.

A fixed reader mounted at a warehouse dock door can automatically log every single tagged pallet that comes in or goes out. You get a perfect, real-time record of inventory movement with almost 100% accuracy and zero human effort.

Handheld (Mobile) RFID Readers

These are portable, scanner-gun-style devices that let you take the reader to the assets. They are perfect for jobs that require mobility, like doing inventory counts on shelves, spot-checking stock, or hunting for a specific misplaced item. A worker can walk down an aisle and scan an entire rack in just a few seconds.

The growth here is huge. The global asset tracking market, which leans heavily on RFID, was valued at USD 24.14 billion and is expected to hit USD 51.59 billion by 2030. RFID is a major driver of this market, proving it’s the go-to solution for modern asset management. You can find more insights about the asset tracking market and its impressive growth online.

Key Factors for a Successful RFID Implementation

So, you’re ready to jump into RFID for tracking your assets. That’s great, but it involves a bit more than just slapping tags on things and buying a reader. A truly successful setup, one that doesn't end in frustration and wasted money, comes down to smart planning that fits your specific environment. If you ignore things like physical interference, future growth, or hidden costs, you can quickly derail the whole project.

A solid strategy tackles these challenges head-on from day one. By thinking through the potential roadblocks, you ensure your RFID system actually delivers the accuracy and reliability you need. This is what separates a system that just looks good on paper from one that genuinely works in the real world.

Navigating Environmental Challenges

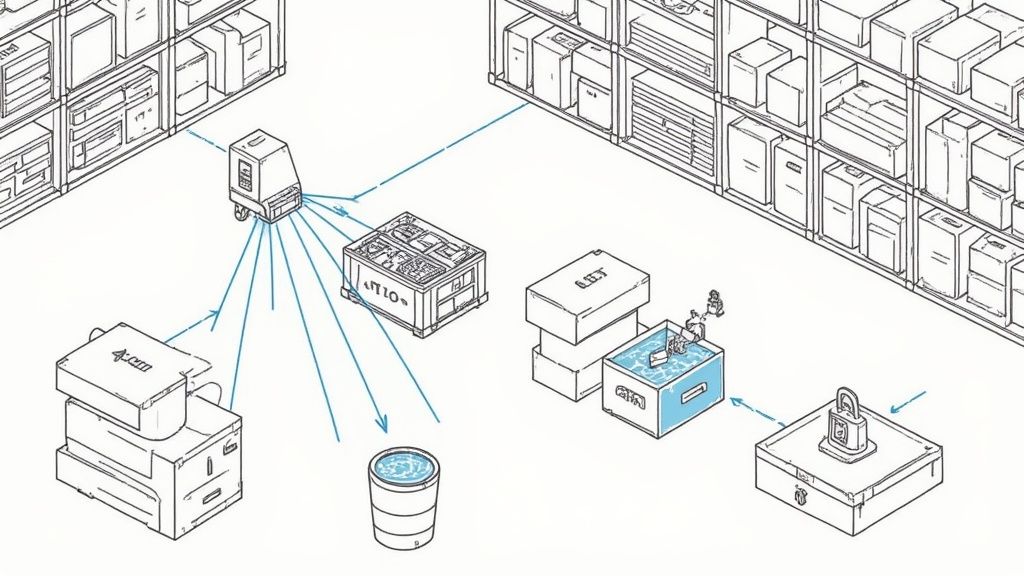

Radio waves can be finicky, and your physical space has a huge say in how well your RFID system performs. The two biggest troublemakers are metal surfaces and liquids. Both can either reflect or absorb the radio waves, making it impossible for a reader to get a clean signal from a tag.

For instance, if you stick a standard RFID tag directly onto a metal filing cabinet or a container full of water, you'll likely get spotty reads, if any at all. This is one of the most common failure points for a poorly planned system.

Fortunately, there are proven ways to get around this:

- Use Specialized Tags: You can buy "on-metal" tags designed with a built-in buffer to work perfectly on metallic surfaces. Likewise, other tags are made specifically for items with high liquid content.

- Adjust Tag Placement: Sometimes, the fix is as simple as creating a little space. Using a foam spacer or a plastic mount to lift the tag off the problem surface can create just enough of an air gap to do the trick.

- Optimize Reader Positioning: Don't be afraid to experiment. Changing the angle and location of your reader antennas can help you find a clearer line of sight to your tags, bypassing whatever is getting in the way.

Planning for Future Scalability

When you first start with RFID for tracking assets, it’s tempting to solve only the problem you have right now. But a system that works for 500 items might completely fall apart when you need it to track 5,000. A smart system is built to grow with you.

Planning for scalability means picking hardware and software that can handle more tags and more data down the road without forcing you into a costly overhaul. This is especially critical in fast-growing industries. The data center world, for example, is one of the fastest-growing markets for RFID asset tracking. It's projected to explode from USD 2.0 billion to USD 9.0 billion by 2030, all because they need to manage thousands of servers and devices. You can read more about this trend in the global strategic business report on Data Center RFID.

Understanding the Total Cost of Ownership

The price tag on the hardware is just the beginning. To really understand the investment, you need to look at the total cost of ownership (TCO) over the system's entire life. This gives you a much more honest financial picture.

A common mistake is to get fixated on the low per-tag price of passive RFID without factoring in the powerful readers, smart software, and professional setup needed to make it all work. You have to look at the whole picture.

Your TCO should cover three main areas:

- Initial Investment: This is all the upfront stuff, including tags, readers (both fixed and handheld), antennas, and any software licenses.

- Implementation Costs: Think of this as the setup fee. It includes site surveys to map out your space, system installation, and getting everything configured correctly.

- Ongoing Expenses: This is the long-term part. Budget for replacing lost or damaged tags, software maintenance or subscription fees, and any hardware repairs or upgrades you might need later on.

Ensuring Data and System Security

Your asset data is valuable, so keeping your RFID system secure is non-negotiable. An open system could let anyone see sensitive inventory information or, even worse, allow someone to tamper with your records.

Good security isn't just one thing; it's a layered approach. Data encryption is essential, as it scrambles the information as it zips between the tag, reader, and software, making it gibberish to anyone trying to eavesdrop. On top of that, access controls in your software ensure that only people with the right permissions can view or change asset data, giving you a secure and trustworthy tracking system.

Comparing RFID with Barcodes, QR Codes, and Bluetooth

When you're looking into RFID for tracking assets, it’s natural to wonder if it's overkill. Is it always the best tool for the job, or could a simpler, cheaper technology work just as well? The honest answer is: it depends entirely on what you’re trying to do.

Making the right choice isn’t about picking the tech with the longest feature list. It's about understanding how these tools perform in the real world. Let's break down how RFID stacks up against the usual suspects: the ever-present barcodes and QR codes, and the newer kid on the block, Bluetooth Low Energy (BLE).

RFID Versus Barcodes and QR Codes

Barcodes and their boxy cousins, QR codes, are the grizzled veterans of asset tracking. They are dirt cheap (you can literally print them on your home office printer) and everyone knows how to use them. But they have one massive weakness: they demand line of sight. You have to physically point a scanner at each and every code to get a read.

Imagine trying to inventory a storage unit crammed with boxes. With barcodes, you’d be pulling boxes out one by one, turning them over, and hunting for that little label to scan. It’s slow, frustrating, and a recipe for missed items.

This is exactly where RFID feels like magic. An RFID reader can blast through cardboard, plastic, and fabric, scanning dozens or even hundreds of tags at once. That same storage unit inventory becomes a quick walk-through. Swing a handheld reader around for a few seconds, and you’ve captured everything without moving a single box.

The core difference is simple: Barcodes answer the question, "What is this specific item I'm looking at?" RFID answers, "What items are here in this general area?"

This highlights their perfect roles. Barcodes and QR codes are fantastic for individual checkpoint scans, like groceries at a checkout. But for bulk inventory or finding a specific item buried in a pile of others, RFID is in a league of its own. To get a better feel for the labels themselves, check out our guide on what are asset tags and the different forms they can take.

RFID Versus Bluetooth Low Energy

A more modern showdown is between RFID and Bluetooth Low Energy (BLE). Both use radio waves and don't need a direct line of sight, but they operate on completely different principles and are built to solve different problems.

Think of BLE beacons as tiny lighthouses. They constantly broadcast a signal, shouting "I'm here!" to any listening device, like your smartphone. This makes them perfect for continuous, real-time location monitoring over larger spaces. A hospital, for instance, could use BLE tags to see a live "dot on a map" showing where every wheelchair and IV pump is at that exact moment.

Most RFID systems, on the other hand, are checkpoint-based. A passive RFID tag is silent until it passes through the energy field of a reader, where it wakes up and reports in. This makes RFID incredibly fast and efficient for confirming presence. Did every tool make it back into the work truck? Is every server rack accounted for in the data center? RFID answers these questions in seconds.

Here’s a simple way to think about their strengths:

- BLE excels at: Live, "dot-on-a-map" tracking of valuable assets as they move around a defined area. Its power is in continuous visibility.

- RFID excels at: Performing lightning-fast, high-volume counts at specific checkpoints or doorways. Its power is in unmatched speed for bulk scanning.

So, the choice comes down to your goal. If you need to know exactly where a specific, high-value asset is right now, BLE is probably your answer. But if your goal is to confirm the presence of hundreds of items in a room in the blink of an eye, nothing on the market beats the raw efficiency of an RFID system.

Your Step-by-Step RFID Implementation Plan

Jumping into an RFID system to track your assets can feel like a massive undertaking. But if you break it down into a clear, step-by-step plan, the whole process becomes much more manageable and sets you up for success. This roadmap will walk you through everything, from the initial idea to a fully functioning system that actually solves your problems.

The trick is to be methodical. You have to start by understanding exactly what you're trying to accomplish. Don't just throw technology at a problem; define your goals. Are you trying to speed up inventory counts, stop losing expensive equipment, or automate your check-in and check-out process? Get specific.

Phase 1: Define Your Goals and Scope

Before you even think about buying a single tag or reader, you need to define what a "win" looks like for you. This planning phase is easily the most critical step, and it will guide every decision you make from here on out. A vague plan is just a recipe for failure.

Start by asking yourself some pointed questions:

- What exactly are we tracking? Are you focused on high-value IT equipment, a fleet of tools, or thousands of tiny inventory items? The answer dramatically changes your hardware choices.

- What problem are we truly solving? Is the main issue that misplaced tools are causing project delays? Or are inaccurate inventory counts creating financial headaches? Pinpoint the pain.

- What’s our real budget? Be honest about the total cost, which includes hardware, software, installation, and the maintenance to keep it all running.

Answering these questions helps you build a tight project scope. This is your best defense against "scope creep," that all-too-common problem where a project balloons in size and complexity, blowing up your budget and timeline.

Phase 2: Conduct a Thorough Site Survey

Every physical space has its own unique quirks that can mess with RFID technology. Think of a site survey as a reconnaissance mission. You're mapping out potential signal interference from things like metal shelving and water, both of which are notorious for blocking or reflecting radio waves.

During this phase, an expert will walk through your facility to find the best spots for fixed readers, figure out the optimal antenna placement, and test different types of tags on your actual assets. This step is absolutely essential if you want the high read rates and accuracy that make a system reliable.

A professional site survey can be the difference between a system that achieves 99% accuracy and one that barely gets a consistent read. It finds and fixes environmental problems before you've sunk a ton of money into hardware.

Phase 3: Run a Small-Scale Pilot Project

Whatever you do, don't attempt a full-scale rollout right out of the gate. A pilot project is your secret weapon. It's a small, controlled test of your RFID system in a limited area, maybe a single room or just one category of assets.

This trial run is your chance to:

- Validate Your Hardware Choices: Confirm that the tags and readers you picked actually perform as expected on your stuff, in your environment.

- Test Your Workflow: See how the system fits into your team's daily routines. You'll quickly spot any adjustments you need to make.

- Work Out Kinks Early: It’s so much easier to solve an unexpected software glitch or tag placement issue on a small scale before it becomes a massive headache for the whole organization.

A successful pilot builds confidence across the team and gives you the hard data you need to justify the larger investment.

Phase 4: Integrate and Deploy

Once your pilot project is a proven success, it’s go-time. This is when you'll tag all the designated assets, install the fixed readers based on your site survey plan, and train your team on how to use the new system. A huge piece of this phase is software integration. For home users, exploring different use cases for home inventory management can spark great ideas for how to make everything work together seamlessly.

The RFID software, often called middleware, needs to connect smoothly with your existing systems, whether that's an inventory platform or an ERP. This connection ensures all the asset data your readers collect is automatically fed into the business software you already rely on. This creates a single source of truth and unlocks the full power of your new system.

Common Questions About RFID Asset Tracking

Even with a solid plan, jumping into a new way of doing things like RFID for tracking assets always brings up a few last-minute questions. Think of this as the FAQ section where we tackle the most common "what ifs" and "how does..." that pop up. Getting these points cleared up can be the difference between a smooth rollout and a frustrating one.

How Durable Are RFID Tags in Harsh Environments?

This is one of the biggest reasons people choose RFID in the first place. Compared to a paper barcode, these tags are incredibly tough. Modern RFID tags aren't just flimsy stickers; they're often encased in hard plastics, ceramics, or even flexible rubber. This armor makes them highly resistant to the daily abuse of industrial life, including impacts, extreme heat and cold, moisture, and chemical exposure.

This resilience is what makes them so reliable in demanding spots. Tags on a factory floor can handle constant vibrations and grime. Tags on outdoor equipment can bake in the sun and get soaked by rain without missing a beat.

There are even specialized "on-metal" tags designed to work perfectly when stuck directly to metallic surfaces, which is a classic weak spot for standard RFID. You can even find tags so tiny they can be embedded directly inside tools, protecting them from the inside out. The trick is simply to match the right tag to your environment.

Can RFID Track My Assets Globally Like GPS?

This is a really common mix-up. The short answer is no. RFID systems are fundamentally different from GPS and aren't built for tracking things in real-time across the globe.

RFID is a proximity-based technology. Its job is to tell you when an asset is near a reader, a range that can be anywhere from a few inches up to about 30 feet for typical passive systems. Think of it as a super-fast, automated check-in system. It's perfect for confirming that an asset is in a specific room, on a particular warehouse shelf, or passing through a loading dock door. It answers the question, "Is this item here?" with lightning speed.

For tracking a shipping container on a cross-country trip, you’d need something like GPS or a cellular tracker. While some high-end systems do merge active RFID with GPS for the best of both worlds, a standard RFID setup is for local, not global, tracking.

RFID gives you the "last known location" within your building with incredible accuracy. GPS gives you a live "dot on a map" anywhere in the world. They're two different tools for two very different jobs.

What Is the Real-World Read Accuracy of an RFID System?

While the technology can hit near-perfect read rates, achieving over 99% accuracy in the real world isn't automatic. It all comes down to proper system design and setup. A lot of things can get in the way.

The usual culprits are environmental interference. As we've mentioned, radio waves can be blocked or distorted by metal and liquids. If you slap a standard tag on a metal keg or a crate of water bottles, you’re going to get missed reads. The orientation of the tag matters, too. If it's not facing the reader's antenna correctly, it might not get picked up consistently.

To get those high accuracy numbers, you have to be deliberate:

- Conduct a Site Survey: An expert needs to walk your facility to map out potential interference spots and find the best places for readers and antennas.

- Select the Correct Tags: This is non-negotiable. Using on-metal tags for metal items or liquid-resistant tags for fluids is critical.

- Run a Pilot Project: Before you go all-in, test your setup on a small scale. This is your chance to find and fix any accuracy hiccups before deploying everywhere.

With careful planning and a bit of fine-tuning, you can absolutely build an incredibly reliable system. That pilot phase is where you work out the kinks and dial everything in.

How Does RFID Data Integrate with My Existing Software?

Modern RFID systems are built to play nicely with the software you already use; they don't operate in a vacuum. The magic happens through a piece of software often called middleware. This is the brain of the whole operation. It sits between the RFID readers and your main business software.

The middleware is crucial. It takes the raw, messy data from the readers and cleans it up. For example, it filters out the hundreds of duplicate reads that happen when a tag sits in front of a reader for a few seconds. Then, it turns that clean data into a meaningful event, like, "Asset XYZ-123 just passed through the loading dock door at 10:15 AM."

This polished, useful information is then sent over to your main systems, such as your Enterprise Resource Planning (ERP), Warehouse Management System (WMS), or any other inventory tool. This connection usually happens through an Application Programming Interface (API), which lets the two systems talk to each other automatically. The result is seamless, real-time data flow that eliminates manual entry, cuts down on human error, and gives your team instant visibility right inside the tools they use every day.

Ready to bring this level of clarity and control to your own space? Vorby uses smart technology to help you create a complete, searchable inventory of everything you own. Stop searching and start finding. Discover how easy it is to get organized.