Using a barcode for inventory management is like giving every single item you own a unique digital fingerprint. It’s the secret to transforming a chaotic stockroom, or a messy garage, into a surprisingly organized and efficient space. The system is a simple but powerful combination of barcode labels, scanners, and software that work together to track your stuff accurately and instantly. It’s the end of slow, error-prone manual counting.

How Barcode Inventory Management Works

Think about trying to manage a storeroom using just your memory, or maybe a pen and a crumpled piece of paper. You’d waste hours counting things, searching for misplaced items, and fixing frustrating data entry mistakes. That manual approach isn't just slow; it's a recipe for human error, which can lead to running out of something you need, overstocking on things you don't, and a whole lot of wasted money.

A barcode system cuts through all that noise by creating a reliable, high-speed link between your physical items and your digital records.

At its heart, the system is a trio of components working in perfect harmony. It all begins with the barcode label itself, a simple tag that holds key data about an item. This label acts as its unique ID card. It's a concept that goes beyond just inventory; you can learn more about how these tags are used in our detailed guide on asset tags.

The Key Components in Action

Next up is the hardware scanner. This could be a heavy-duty, dedicated device built for a bustling warehouse, or it could be the smartphone you already have in your pocket. When you scan a barcode, the device reads the pattern of lines and spaces, instantly translating it into digital information.

That information is then zapped over to the third, and most critical, component: the central software. This is the brain of the whole operation, a real-time database for your entire inventory. Every scan updates the system, tracking an item's journey from the moment it arrives to the moment it leaves.

The core idea is simple but incredibly effective. Every scan provides an immediate, error-free update to your inventory count. This replaces guesswork with hard data, paving the way for precise stock management and smarter decisions.

From Chewing Gum to a Global Standard

This tech might feel modern, but its roots stretch back decades. The barcode really started taking off in the 1970s, marking a massive shift in how businesses operated. Before this, inventory counts were so disruptive that companies often had to shut down for days just to get a handle on their stock.

The first official scan of a Universal Product Code (UPC) happened on June 26, 1974, on a pack of Wrigley's Juicy Fruit gum. That simple beep at a checkout counter in Ohio kickstarted modern inventory management as we know it. This single scan proved how technology could slash the time and labor needed to track stock, paving the way for the efficient systems we all rely on today. By turning a tedious manual chore into a slick automated process, barcodes laid the foundation for a much more accurate and responsive supply chain.

The Three Core Components of a Barcode System

When you hear “barcode system,” it’s easy to picture just the black-and-white striped labels. But that’s only one piece of the puzzle. A truly effective system is a trio of interconnected parts, each playing a critical role in turning a physical item into a digital record.

When these three components work in harmony, they create a fast, accurate flow of information that can completely change how you track your belongings.

Think of it like a conversation. The barcode is a word written in a special language, the scanner is the translator, and the software is the brain that understands and acts on the translated message. Let’s break down each of these core components.

Component 1: The Barcodes Themselves

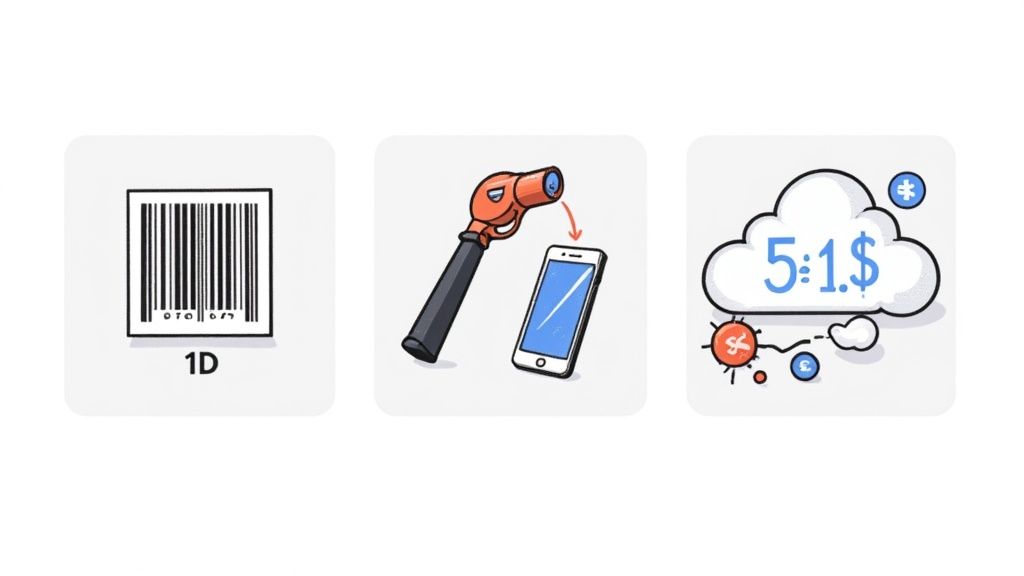

First up is the barcode label itself, which acts as a unique fingerprint for each item. But not all barcodes are created equal. They fall into two main categories, each with its own strengths depending on what you need to track.

The most familiar type is the 1D (one-dimensional) barcode. These are the classic vertical lines you see on pretty much every product at the grocery store, like a UPC (Universal Product Code) or Code 39. They’re simple, cheap to print, and perfect for basic tracking.

The big catch with 1D barcodes? They can only hold a tiny amount of text-based data, typically around 20 to 25 characters. That’s usually just enough for a product number or SKU, and not much else.

For more complex needs, we turn to 2D (two-dimensional) barcodes, like QR codes or Data Matrix codes. These square-shaped codes are read both horizontally and vertically, which lets them pack in a massive amount of information.

A standard QR code can hold over 2,500 numbers or 1,500 letters and numbers. That means you can embed not just a product code, but also things like website links, batch numbers, manufacturing dates, or detailed descriptions right into the code itself.

To help you choose, here’s a quick rundown of the most common barcode types you'll encounter.

Comparing Common Barcode Types for Inventory

This table compares the most common 1D and 2D barcodes used in inventory management, highlighting their data capacity, common applications, and key advantages.

| Barcode Type | Category | Data Capacity | Common Use Case | Key Advantage |

|---|---|---|---|---|

| UPC | 1D | Low (12 numeric digits) | Retail products, groceries | Universally recognized, simple |

| Code 39 | 1D | Low (20-25 characters) | Internal asset tracking | Alphanumeric capability |

| QR Code | 2D | High (up to 2,509 numbers) | Product info, marketing, logistics | Stores rich data, scannable from any angle |

| Data Matrix | 2D | High (up to 2,335 characters) | Small electronics, parts | High data density in a very small size |

Each type has its place, but for versatile home inventory, the high data capacity of a QR Code is hard to beat.

Component 2: Scanning Hardware

Once you’ve got your items labeled, you need a way to read those codes. This is where scanning hardware comes in, acting as the bridge between your physical stuff and your digital records. The options range from heavy-duty industrial tools to the device you’re probably holding right now.

In high-volume places like warehouses or big retail stores, dedicated barcode scanners are king. These devices are built for one purpose: scanning thousands of codes a day, quickly and reliably. They’re tough, fast, and designed to survive drops and constant use.

But for most of us, there's a much more accessible option: the smartphone. A modern smartphone camera, paired with a smart inventory app like Vorby, can easily function as a powerful barcode and QR code scanner. This approach is incredibly convenient and costs nothing extra, making it perfect for home inventory projects, small businesses, or anyone organizing a garage or storage unit.

The key is picking the right tool for the job. While a rugged scanner is essential for a busy loading dock, your phone is the perfect, always-on-you solution for cataloging what’s in your home.

Component 3: Inventory Management Software

The final, and arguably most important, component is the inventory management software. This is the system's brain, the central hub where all that scanned data is collected, organized, and turned into something useful. Without it, a barcode is just a pattern, and a scan is just a meaningless beep.

This software is where the magic happens, handling several critical jobs:

- A Central Database: It keeps a real-time record of every single item, including what it is, where it is, and how many you have.

- Transaction Logging: Every scan, whether you’re adding a new item, moving a box, or using something up, is instantly logged, keeping your inventory levels perfectly up to date.

- Reporting and Insights: Good software can show you trends, help you find things instantly, and make smarter decisions about what you own or need to buy.

- System Integration: More advanced platforms can connect with other tools, like shopping lists or financial apps, to create a seamless flow of information.

This is what turns raw data into actionable intelligence. The software provides the visibility you need to finally know what you have and where to find it. Together, these three components (barcodes, scanners, and software) form a complete system that brings precision and efficiency to any inventory challenge, big or small.

Why Bother with a Barcode System? It’s a Game Changer.

Let’s be honest. Moving from a spreadsheet you kind of keep updated to a full-blown barcode system feels like a huge leap. But it’s more than just a simple upgrade; it’s a total shift in how you manage your stuff, and the payoff is real. A barcode system brings a level of speed and accuracy that manual tracking just can't touch. The benefits start small but quickly ripple out, improving everything from day-to-day tasks to your bottom line.

This transformation hits four key areas: It wipes out most human error, makes everything move dramatically faster, gives you a crystal-clear, real-time picture of your stock, and ultimately puts money back in your pocket.

Drastically Reduce Human Error

We’ve all been there. A simple typo when keying in a part number or a miscount during a stock check creates phantom inventory or leads to an unexpected "out of stock" crisis. These tiny mistakes pile up, creating frustrating discrepancies that take forever to track down and fix.

A barcode system pretty much puts an end to that. Scanning an item is a direct, one-to-one transfer of data. No numbers to transpose, no quantities to misread. The system logs exactly what was scanned, making your digital record a perfect mirror of what’s physically on the shelf.

This isn't just a minor tweak, it's about building a foundation of data integrity. When you eliminate the main source of inventory mistakes, you create a reliable database you can actually trust to make important decisions.

Achieve Unprecedented Speed and Efficiency

Think about the last time a big shipment arrived. Someone had to identify each product, count every single item, find the right line on a spreadsheet, and then type in the data. The whole process is painfully slow, tedious, and pulls your team away from work that actually adds value.

With barcodes, that same job boils down to a few quick zaps of a scanner. An entire pallet of goods can be checked in within minutes, not hours. This incredible speed boost applies to every single inventory task.

- Order Picking: Fulfilling orders gets exponentially faster when you can scan items to instantly verify you’ve grabbed the right product.

- Cycle Counts: Regular inventory checks become way less disruptive and can be done in a fraction of the time.

- Asset Tracking: Finding and checking out tools or equipment is instantaneous, which gets your whole team moving more efficiently.

All this newfound efficiency means you can handle way more work without having to hire more people.

Gain Real-Time Inventory Visibility

One of the biggest headaches with manual inventory is the delay between something happening in the real world and you updating the spreadsheet. This information lag means you’re always flying blind, working with outdated data and never really knowing what you have in stock right now.

Barcode systems fix this by delivering real-time visibility. Every single scan updates your central inventory software immediately. This instant feedback loop empowers you to make smarter, more proactive decisions. You can confidently check stock levels from anywhere, set up automatic alerts for when you're running low, and stop tying up cash in extra inventory that’s just gathering dust.

If you're curious about taking this a step further, you can check out our guide on how RFID technology tracks assets.

Realize a Clear Return on Investment

When you add it all up (fewer errors, faster operations, and real-time data), you get a clear and measurable return on investment (ROI). The financial impact is well-documented. Industry analyses show businesses that ditch manual methods for barcodes see up to 67% fewer inventory mistakes, which is a direct cost saving. On top of that, order picking speeds often jump by about 30%, and the time wasted on manual reconciliations can be cut by an average of 4 to 6 hours per week. You can find more insights on the benefits of barcode inventory management on finaleinventory.com.

Ultimately, the system pays for itself through saved labor, optimized stock levels, and just plain better accuracy across the board.

Your Step-by-Step Implementation Plan

Making the jump to a barcode system can feel like a huge undertaking, but if you break it down into a clear, actionable plan, the whole process becomes much more manageable. When you tackle it one step at a time, you can build a reliable and efficient system that’s actually tailored to how you work. This roadmap will walk you through everything, from the initial planning stages to getting your team comfortable with the new workflow.

This whole process is about making a direct line from chaos to control.

As you can see, shifting from manual lists to a scanning-based workflow means fewer mistakes, faster counts, and a much clearer picture of what you actually have in stock.

Step 1: Assess Your Needs and Choose Software

Before you even think about buying a label or a scanner, the very first step is to figure out what you need this system to do. Are you a small shop tracking retail products, or a homeowner trying to finally catalog all the tools in your workshop? The answer will point you to the right software, which is the brains of the entire operation.

A simple setup might just need basic check-in and check-out functions. But if your needs are a bit more complex, you might be looking for features like low-stock alerts, kitting (which is just bundling different items together), or the ability to connect with other business tools.

The goal is to find a system that solves your current headaches without being a complicated mess. A system that feels intuitive and is easy to pick up is far more likely to stick.

Look for software that can grow with you. A platform that can generate and scan different kinds of codes is a huge advantage. To get a feel for what’s possible, see how easy it is to generate and use QR codes for inventory when you have the right tools.

Step 2: Select the Right Hardware and Labels

Once you’ve got your software picked out, you can move on to the physical tools: the barcode scanners and the labels you’ll stick on everything. The biggest factor here is your environment. A busy warehouse probably needs rugged, drop-proof scanners built for constant use.

For pretty much every other scenario, including home inventory or a small business, a modern smartphone is more than enough. A good app turns the device you already carry into a powerful inventory tool, saving you a chunk of change and making the setup way simpler.

Next up, labels. The material and the glue need to match both your items and where they’re stored. For instance:

- Paper Labels: These are cheap and perfect for things stored indoors in a dry spot, like products on a retail shelf.

- Polyester or Vinyl Labels: These are way tougher. They can handle moisture, chemicals, and getting scraped up, making them ideal for tools, outdoor gear, or anything in a garage.

- Removable Labels: These are great for temporary items or products where you don’t want to leave sticky gunk behind.

Getting the right mix of hardware and labels from the start ensures your system will actually hold up to daily use.

Step 3: Design Your Barcode Logic

This step is all about creating a consistent structure for your barcodes, often called a Stock Keeping Unit (SKU) format. A smart SKU is logical and easy to decipher at a glance, embedding useful info right into the code itself. This is your secret weapon against confusion and messy data.

For example, a SKU for a t-shirt could look like TS-BLU-M-001. That format clearly tells you the item type (T-Shirt), color (Blue), size (Medium), and gives it a unique number (001). Creating a standard format like this means every single item gets cataloged the same way, every time.

Figure out what information is most critical for you to know instantly and build your logic from there. The number one rule here is consistency.

Step 4: Tag Your Existing Inventory

This is usually the most time-consuming part of the job, but it’s absolutely essential. You have to go through all of your existing stock and stick a unique barcode label on every single item. This is how you create the clean, accurate foundation your new system will be built on.

It’s also the perfect time to do a full physical inventory count. As you tag each item, scan it into your new software. This ensures your starting numbers are 100% accurate. It’s a lot of upfront effort, I know, but a meticulous tagging process is what prevents "ghost" inventory and other data nightmares down the line.

Step 5: Train Your Team

A perfect system is worthless if nobody knows how to use it right. The final step is to train yourself and anyone else who will be using it. Create simple, clear instructions for the most common tasks, like receiving new stock, pulling items for an order, or doing a quick spot-check (a cycle count).

Walk through each process together. Make sure everyone understands the workflow and feels comfortable using the scanner and the software. Drive home the importance of scanning every item, every time. A little bit of training at the start pays off big time by making sure the system is used correctly from day one.

Best Practices for Long-Term Success

Getting your barcode system up and running is a huge win, but the real magic happens over time as you maintain it. A little discipline turns a good setup into an indispensable one. Think of it like a car; you can’t just buy it and expect it to run forever without oil changes. These are the "oil changes" for your inventory system that ensure it runs smoothly for the long haul.

https://www.youtube.com/embed/OpcX8iNPE5M

Create Standard Operating Procedures

The secret to clean, reliable inventory data? Consistency. If one person logs new items differently than another, you’re creating tiny data fractures that will eventually crack your whole system. Standard Operating Procedures (SOPs) eliminate that risk by making sure everyone handles inventory the same way, every single time.

Your SOPs don't need to be a hundred pages long. They just need to be clear, step-by-step instructions for the most common tasks.

- Receiving New Stock: What’s the exact process from the moment a box arrives? Detail how to unload it, scan items into the system, and get them to the right shelf.

- Picking and Packing Orders: Outline how to find items, scan them out of inventory, and prep them for shipment. This keeps your counts perfect.

- Returning Items to Stock: Define the procedure for scanning returned goods back into the system so they don't end up in a forgotten corner.

When every move is standardized, guesswork disappears, and your data stays trustworthy.

Embrace Regular Cycle Counts

Forget the nightmare of shutting down your entire operation for a massive, weekend-long physical inventory count. A well-run barcode system makes that ordeal obsolete. The smarter approach is cycle counting.

Cycle counting is simple: you check a small, manageable section of your inventory on a regular basis, maybe one shelf a day or one aisle a week. Over time, you cover your entire stock without the chaos and disruption of a full-blown shutdown. This practice helps you catch and fix small discrepancies before they snowball into huge problems.

Think of it as routine maintenance for your inventory data. A few minutes of scanning each day prevents the massive headaches that build up when you only count everything once or twice a year.

Maintain Your Hardware and Supplies

Your fancy software is useless if the physical tools fail. A scanner with a smudged lens or a printer that runs out of labels can grind your entire workflow to a halt, creating costly bottlenecks. Proactive maintenance is non-negotiable.

Get in the habit of wiping down your scanner lenses and checking printer heads for wear. Even more important, never let yourself get caught without essential supplies. Keep a healthy stock of label rolls and printer ink. There's nothing worse than having a huge shipment arrive only to realize you can't print a single barcode for it.

Integrate for Seamless Operations

A barcode system truly comes alive when it talks to your other business tools. The real power is unlocked when you integrate your inventory software with your accounting platform, your e-commerce store, or your sales software. This creates a seamless, automated flow of information across your entire business.

This kind of integration used to be the exclusive domain of giant retailers. But by the 1990s, as scanners and PCs became more affordable, the door opened for small and midsize businesses. The trend continued, and today's software makes these connections easier than ever. You can learn more about the history of inventory management on peaktech.com.

When your systems are connected, a sale on your website can automatically update your stock levels, which in turn can trigger a purchase order for more supplies. It’s how you build a truly data-driven operation that runs itself.

Answering Your Top Questions About Barcode Inventory Systems

As you get closer to setting up a barcode system, the questions start popping up. It's totally normal. Shifting how you track your belongings, whether at home or for a side hustle, involves a few key decisions. We've gathered the most common questions we hear and answered them in a straightforward, practical way to help you get started with confidence.

Let's cut through the noise and get you the answers you actually need.

Can a Smartphone Really Work as a Barcode Scanner?

Absolutely. In fact, for most people, it's the smartest option. Modern smartphone cameras, paired with a solid inventory app, are more than capable of scanning both 1D and 2D barcodes with surprising speed and accuracy.

Why is this the way to go?

First off, it's a huge money-saver. You're using the powerful device that’s already in your pocket instead of dropping hundreds on a dedicated, industrial-style scanner. Second, it's just plain convenient. Your phone is always with you, which means you can add new items or do a quick stock check on the fly, without hunting down specialized gear.

Sure, a dedicated scanner might shave off milliseconds in a high-volume warehouse, but for home inventory, a small business, or tracking your personal assets, your smartphone is the perfect tool for the job. The real magic isn't the hardware; it's the software that makes the scanning feel effortless.

What’s the Difference Between a Barcode and a SKU?

This is a fantastic question because these two things are partners, but they have very different jobs. The easiest way to think about it is like this: the barcode is the language, while the SKU is the message it's speaking.

A SKU, or Stock Keeping Unit, is a unique code (usually a mix of letters and numbers) that you create to identify a specific item. For example, you might create the SKU TSHIRT-RED-LG-01 for a large red t-shirt. It's human-readable, meaning you can look at it and know exactly what it is.

A barcode is simply the machine-readable version of that SKU. When you generate a barcode, you’re translating your unique SKU into a pattern of lines or squares that a scanner can read instantly. The scanner zaps the barcode, deciphers the pattern, and tells your software, "Hey, this is TSHIRT-RED-LG-01."

In short: The SKU is the unique ID you give an item. The barcode is the scannable sticker that carries that ID. One is for your brain; the other is for the machine.

How Much Should I Budget for a Complete System?

The cost of setting up a barcode system can swing wildly, but the good news is you can get started for less than the price of a pizza. Your total investment really comes down to three things: software, hardware, and supplies.

Software: This is where you'll see the biggest price range. Enterprise-level inventory software can run from $50 to over $300 per month. But for personal or small-scale use, many apps offer powerful features at a much friendlier price point.

Hardware: This could be your biggest expense, or it could be $0. If you use your smartphone, you've already got the hardware covered. If you genuinely need a dedicated scanner for a high-traffic environment, you can find basic models for around $150, while rugged, industrial units can climb past $1,000.

Supplies: These are your ongoing costs. A roll of 1,000 thermal labels usually costs between $10 and $25. A simple desktop label printer will set you back around $100 to $300.

For a bare-bones home setup using a smartphone and printing on standard paper, you could be up and running for under $50. A more serious small business setup, with a dedicated label printer and a software subscription, might have an initial cost of $200 to $500, plus a modest monthly fee.

How Do I Add Barcodes to Items That Don't Have Them?

This is where you really take control of your inventory. Many things you want to track, like personal belongings, handmade products, or items in a storage unit, won't come with a manufacturer's barcode. That's perfectly fine; your inventory software is built for this.

The process is simple.

First, you create your own internal SKU for the item, just like we talked about earlier. It helps to come up with a consistent naming system that makes sense to you.

Next, you hop into your inventory app and use it to generate a new barcode based on that SKU. Most platforms let you pick the barcode type (like Code 39 for simple internal codes or a QR code to store more info) and even add text like the item's name right on the label.

Finally, just print the label and stick it on your item. A good app makes this whole process seamless, letting you create unique, scannable IDs for everything from boxes in the attic to the tools on your workbench. This way, every single thing you own can be tracked with a quick, simple scan.

Ready to stop searching and start organizing? With Vorby, you can generate custom QR codes, scan items with your iPhone, and use powerful search to find anything in seconds. Turn your chaotic spaces into a perfectly organized inventory. Start your free 14-day trial and see how easy it can be at https://vorby.com.