Think about the last time you watched a big game. Would you want score updates only once a day? Of course not. You'd have no clue who was winning, what plays were working, or what momentum shifts were happening in real-time. That frustrating delay is exactly how old-school, traditional inventory systems work; they rely on manual counts and updates that are outdated the moment they're finished.

What Is Real Time Inventory Management

In contrast, real-time inventory management is like having a live scoreboard for every single product you own. It gives you a constant, up-to-the-second view of your stock.

Every time an item is sold, received, moved, or even returned, your records update instantly. This system replaces guesswork with certainty, empowering you to make smarter, faster decisions based on what’s happening right now, not what happened yesterday or last week.

The core idea is simple but incredibly powerful: knowing exactly what you have, where it is, and how it’s moving gives you a massive advantage. To get a feel for the tech that makes this instant tracking possible, it's worth checking out A Guide to Real-Time Data Processing.

To really grasp the shift, let's compare the old way with the new.

Traditional vs Real Time Inventory Management

The difference between periodic counts and a live system is night and day. One is a blurry snapshot from the past; the other is a high-definition live stream.

| Aspect | Traditional Inventory Management | Real Time Inventory Management |

|---|---|---|

| Data Freshness | Updated periodically (daily, weekly, monthly) | Updated instantly with every transaction |

| Accuracy | Prone to human error, quickly becomes outdated | Highly accurate, reflects the current state |

| Decision Making | Based on historical, often inaccurate, data | Based on live, actionable information |

| Visibility | Limited; blind spots between physical counts | Complete, end-to-end visibility at all times |

| Labor Intensity | Requires disruptive, time-consuming manual counts | Automated tracking reduces manual labor |

| Risk of Stockouts | High, as low stock levels are spotted late | Low, with automated alerts for reordering |

| Overselling | Common problem for e-commerce stores | Prevented by syncing live stock to all sales channels |

This table makes it clear why businesses, and even households, are moving away from the old methods. A real-time system isn't just an upgrade; it's a fundamental change in how you manage your assets.

Beyond the Warehouse Walls

While "inventory management" might bring to mind massive warehouses and logistics empires, the principles are surprisingly universal. They work just as well for a small e-commerce business running out of a garage as they do for a family trying to organize their pantry, closets, and storage unit.

The goal is always the same, just on a different scale:

- Prevent Overselling: For a business, this means no more angry customers ordering an item that's actually out of stock. At home, it means not promising a friend you have an extra HDMI cable when you actually don't.

- Minimize Stockouts: A real-time alert can trigger a reorder when you're down to your last box of cereal or your last T-shirt in size Medium. This prevents missed sales and last-minute grocery runs.

- Reduce Holding Costs: By knowing exactly what you have, you avoid overstocking. For a business, this frees up cash and warehouse space. For a home, it means not buying a fifth bottle of ketchup when four are already hiding in the pantry.

- Enhance Experience: In business, it’s about fast, accurate order fulfillment. At home, it’s the simple joy of finding what you need without a frustrating 20-minute search.

In essence, a real-time system acts as the central nervous system for your inventory. It connects every action (from a sale on your website to a new shipment arriving, or from using the last of the flour to adding groceries to the shelf) into one cohesive, instantly updated picture.

This live, dynamic view transforms your inventory from a static list of things into an active, manageable resource. It gives you the clarity to operate efficiently, cut down on waste, and respond quickly to what you actually need.

The Core Benefits of Instant Inventory Visibility

Switching to real-time inventory management is more than just getting up-to-the-minute numbers. It fundamentally rewires how your entire operation runs. The biggest immediate win is a massive jump in inventory accuracy. When every item's movement is tracked the second it happens, the gap between what your system says you have and what’s actually on the shelf practically vanishes.

This newfound accuracy directly tackles two of the most persistent headaches in inventory control: stockouts and overstocking. Think of a real-time system as a vigilant watchdog, preventing that gut-wrenching moment when a customer orders something that, unbeknownst to you, is already gone.

Slash Stockouts and Eliminate Overselling

Nothing erodes customer trust faster than canceling an order because of an inventory mistake. Overselling is what happens when your sales channels, like your website and a physical store, aren't talking to each other instantly. A real-time system ensures that as soon as an item sells on one channel, it's immediately marked as unavailable on all the others.

At the same time, it helps you dodge stockouts. You can set up automated alerts that ping you the moment an item hits a low-stock threshold. This proactive nudge means you can reorder before you run out, ensuring you never miss a sale because of an empty shelf.

By providing a single, accurate view of inventory at any given moment, real-time systems transform your stock from a source of uncertainty into a reliable, manageable asset. This shift is crucial for maintaining customer satisfaction and protecting your revenue stream.

The financial impact here is huge. Real-time systems can boost inventory accuracy from the typical 75% to 80% you get with manual counts to well into the high-90s. That precision translates directly into cash. One retailer reported a 31% increase in sales conversion after making the switch, simply because customers could finally trust the stock information they were seeing. You can dig into more of these real-world results by exploring in-depth reports on inventory accuracy and efficiency.

Supercharge Operational Efficiency

Just think about all the hours and labor poured into manual inventory tasks, especially the dreaded annual physical count. These events are disruptive, expensive, and notoriously prone to human error. Real-time tracking automates that entire painful process.

Instead of shutting down operations for a massive audit, you can rely on continuous, automated cycle counting. This frees up your team to focus on things that actually grow the business, like customer service, merchandising, or strategic planning. The efficiency gains are crystal clear:

- Reduced Labor Costs: Less time spent on manual counting, hunting for lost items, and fixing data entry mistakes.

- Faster Fulfillment: When you know the exact location of every single item, picking and packing orders gets dramatically faster and more accurate.

- Streamlined Receiving: New stock can be scanned and instantly added to your available inventory, making it ready to sell almost immediately.

This automation puts every part of your workflow on fast-forward, letting you process more orders with greater precision and fewer resources.

Unlock Financial Agility

Finally, instant inventory visibility has a profound effect on your financial health. By preventing overstocking, you stop tying up precious capital in products that are just sitting there, not selling. This creates a positive ripple effect across your finances.

A major benefit is the reduction in carrying costs. These are the hidden expenses of storing unsold inventory, things like warehousing fees, insurance, and the risk of products becoming obsolete or spoiling. With a lean, accurate inventory, these costs shrink dramatically.

This financial discipline leads directly to improved cash flow. Money that was once locked up in excess stock is now free to be invested in other areas of your business, whether that's marketing, product development, or expansion. At the end of the day, a real-time inventory system doesn't just organize your products; it optimizes your capital.

The Tech That Makes Real-Time Happen

To get that live, second-by-second view of your inventory, you need a combination of smart hardware and software working in perfect sync. Think of it like a relay race where each piece of tech flawlessly passes the baton of information to the next, creating a continuous, unbroken flow of data. The race starts by giving every single physical item its own digital identity.

The most familiar players here are barcodes and QR codes. They're the black-and-white patterns you see on pretty much every product. A quick scan with a handheld device, or even just your smartphone, instantly pulls up an item's data, updating its status in your central system whether it’s just arrived, been sold, or moved to a new shelf. They are the dependable workhorses of inventory tracking, offering a cheap and simple way to get your physical goods talking to your digital system.

Beyond the Scan: How RFID Changes the Game

Scanning a barcode is a direct, one-at-a-time action. But Radio-Frequency Identification (RFID) takes a massive leap forward. RFID tags have a tiny microchip and antenna that broadcast information to a reader using radio waves. This means you don't need a direct line of sight to scan each item individually.

Imagine a pallet of tagged products passing through a warehouse door. A reader mounted over the doorway can identify every single item inside every box at once, without anyone ever having to open them. This capability dramatically speeds up jobs like receiving shipments or doing cycle counts, making it a cornerstone for any high-volume operation. To really dig into how this works, check out our guide on using RFID for tracking assets.

This ability to grab data from dozens or even hundreds of items at once is what makes RFID so powerful for building a truly automated real-time inventory management system.

The Rise of Intelligent and Connected Systems

The next layer of tech adds a whole new level of awareness, moving from simply identifying items to actively monitoring their environment and even predicting what you'll need next. This is where the Internet of Things (IoT) and Artificial Intelligence (AI) step in.

IoT sensors are small devices that can keep tabs on conditions like temperature, humidity, or movement. If you're dealing with perishable goods like food or medicine, these sensors are game-changers. They can send an instant alert if a refrigerator’s temperature creeps up, preventing spoilage and protecting your bottom line.

AI then takes all this data, from barcode scans to sensor readings, and turns it into strategic insights. It can:

- Analyze sales patterns to predict future demand with spooky accuracy.

- Flag slow-moving items that are just tying up cash and shelf space.

- Automate reordering by figuring out the perfect moment to replenish stock.

AI acts as the strategic brain of the operation. It doesn't just tell you what you have right now; it helps you decide what you'll need next week, next month, or even next season.

This powerful combination is what's driving huge growth in the market. Projections show the global inventory management software industry is on track to hit around $2.51 billion by 2025, growing at a compound annual rate of nearly 9.6% through 2032. This boom is fueled by the need for better forecasting that helps businesses cut carrying costs and get orders out the door faster. You can find more details on these market trends and their drivers to see where the industry is headed.

The Central Brain: Cloud-Based Software

All this tech, from a simple QR code scan to a complex AI forecast, needs a central hub to connect everything. That's the job of integrated, cloud-based software platforms. These platforms act as the central nervous system, collecting data from every scanner, sensor, and sales channel in real time.

Because the software is in the cloud, this information is available from anywhere, on any device. This ensures everyone from the warehouse floor to the front office is working from the same live, accurate numbers. And the technology is constantly getting smarter; you can explore the potential of leveraging AI for predictive sales and inventory management to see just how advanced these tools are becoming. This centralized, intelligent core is what ties it all together, creating a seamless and powerful inventory ecosystem.

Implementing Your Real Time Inventory System

Making the jump to a real-time inventory system feels like a massive undertaking, but it’s not. When you break it down into clear, manageable stages, the whole process becomes surprisingly straightforward. Think of it less as a single, monumental overhaul and more as a series of deliberate steps that build on one another.

The first and most critical move is to figure out exactly where you are now and what you want to achieve. What are the pain points? Are you constantly running out of stock or, worse, selling items you don’t actually have? Do you waste hours on manual counts that are outdated the second you finish? Pinpointing these problems helps you set specific, measurable goals, ensuring you pick a solution that actually solves your issues.

Choosing the Right Technology

Once your goals are crystal clear, you can start looking at technology that fits your scale and budget. You don't need a massive, enterprise-level system to get started. Modern tools have made real-time management accessible for everyone, from a growing online store to a meticulously organized home.

Keep these key factors in mind as you weigh your options:

- Cost: Look at the whole picture. Balance the initial setup costs, like hardware and software licenses, with the long-term savings you'll get from fewer errors and way more efficiency.

- Complexity: Pick a system that matches your team's (or your own) comfort level. An overly complicated tool that nobody uses is far worse than a simpler one that everyone actually adopts.

- Scalability: Will this system grow with you? Make sure it can handle more products, more users, and maybe even more locations down the road without forcing you to start all over again.

This isn't about grabbing the fanciest tool on the market. It’s about finding the perfect fit for your unique situation.

Setting Up Your System Step by Step

After you've picked your tools, it's time to get your hands dirty. This is the practical phase where you’ll move your existing data, tag all your items, and get the hardware and software talking to each other. A structured approach here is the secret to a smooth rollout.

- Data Migration: First things first, you need to get your current inventory data into the new system. This usually means exporting spreadsheets or database records and then importing them. Honestly, this is the perfect time for a data cleanse. Get rid of old, inaccurate info and obsolete items before they pollute your shiny new system.

- Tagging Your Inventory: Every single item needs a unique digital fingerprint. This is where you’ll slap on barcodes, QR codes, or RFID tags. It's a crucial step that connects each physical thing to its digital record, forming the very foundation of real-time tracking. To do this right, check out our in-depth guide on building a tagging system for inventory.

- Hardware and Software Setup: Next, you'll install and set up your hardware (like scanners or readers) and the software itself. This includes connecting your sales channels, like your website or online marketplaces, and creating automated workflows, such as low-stock alerts and automatic reorder points.

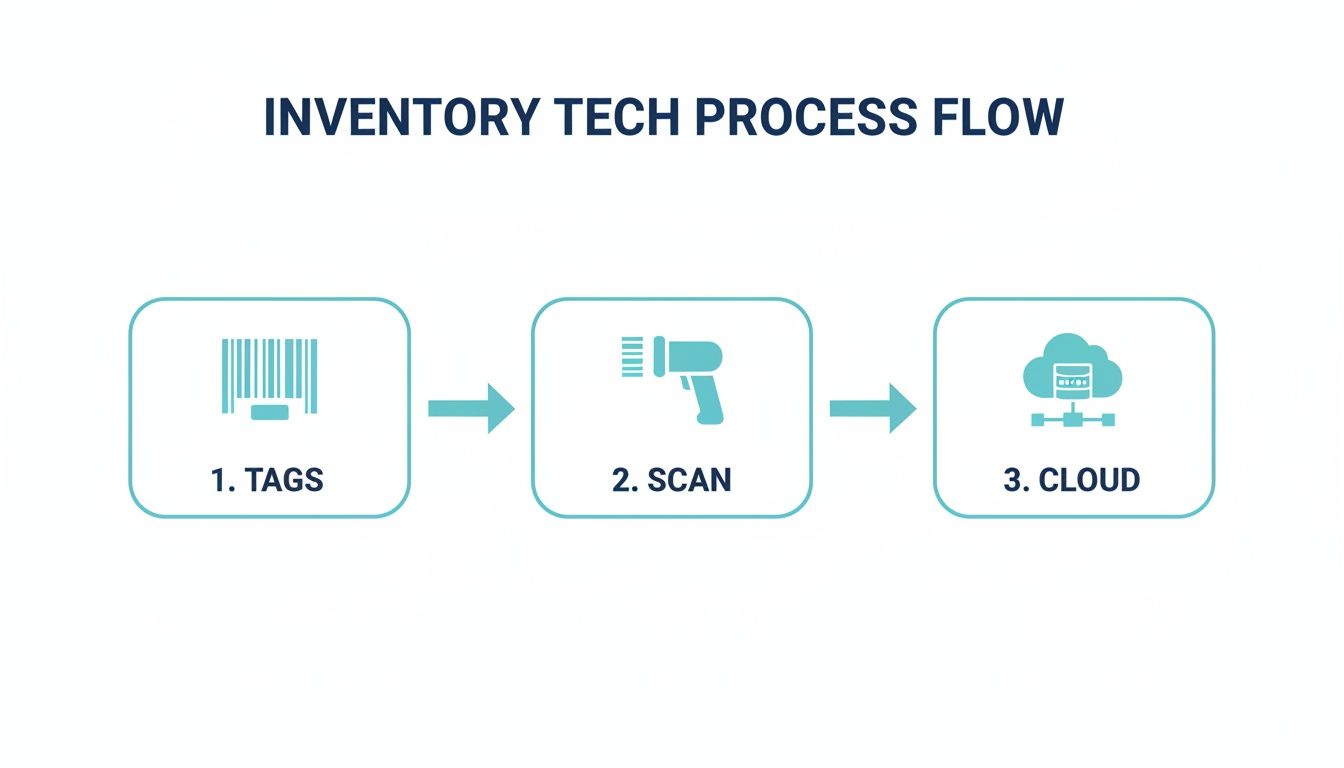

The basic flow is simple, but powerful. The infographic below shows how an item goes from a physical tag to a digital update in the cloud.

This simple three-step loop is the engine that drives real-time visibility, making sure every physical action is instantly mirrored in your digital records.

Ensuring a Successful Adoption

Here’s a hard truth: the technology is only half the battle. A successful rollout lives or dies based on your team’s willingness and ability to use the new system correctly. The best software in the world will fail if it’s not integrated into daily habits.

The human element is the most overlooked, and most important, part of any technology rollout. A system is only as accurate as the data people put into it. That requires consistent, correct use from everyone involved.

To make sure the transition sticks for the long haul, focus on two key areas:

- Comprehensive Team Training: Don’t just show your team how to use the scanners. Explain why it matters. When people understand that accurate scanning prevents angry customer emails and saves them from hunting for lost items, they're far more likely to get on board.

- Workflow Integration: The new system needs to feel like a natural part of the workday, not some annoying extra chore. Weave scanning into existing processes like receiving shipments, packing orders, and handling returns. The goal is to make real-time updates an automatic byproduct of tasks they're already doing.

By thoughtfully planning each stage, from setting goals to supporting your team, you can roll out a real-time inventory management system that delivers real, lasting value.

Measuring Success and Avoiding Common Pitfalls

Putting a real-time inventory management system in place is a massive win, but it’s definitely not a "set it and forget it" solution. To get real value, you have to measure its performance and sidestep the common mistakes that can trip you up. Success isn’t about having the tech; it’s about using it to get tangible results.

You need to know if the system is actually pulling its weight. That means tracking specific Key Performance Indicators (KPIs) that act like a health check for your inventory operations. These metrics turn vague goals like "being more efficient" into hard numbers, showing you exactly where you're winning and where you need to make a change.

Key Metrics to Track Your Success

Monitoring the right data helps you see the return on your investment and sharpen your strategy. Don't try to track everything at once. Just focus on a few critical KPIs that give you a clear picture of performance.

Here are a few metrics that matter most:

- Inventory Turnover Ratio: This tells you how quickly you’re selling through your stock. A higher number is usually a good sign, meaning products are flying off the shelves instead of gathering dust.

- Order Fulfillment Cycle Time: This is the stopwatch for your entire process, from the moment a customer clicks "buy" to the second the package lands on their doorstep. A shorter cycle time is a direct sign of happy customers and a well-oiled machine.

- Carrying Costs of Inventory: This is the hidden cost of owning stuff: storage fees, insurance, and the risk of items becoming obsolete. A good real-time system should slash these costs by helping you keep just enough stock on hand.

Tracking these numbers gives you proof that your system is more than just a fancy tool; it’s a genuine asset that saves money and improves service. You might also want to check out our broader guide on inventory management best practices to get an even fuller picture.

Common Mistakes and How to Avoid Them

Even the most powerful technology will fail if it's implemented poorly. Too many organizations stumble over the same predictable, and avoidable, hurdles. Just knowing what they are is the first step to making sure they don't derail your progress.

One of the biggest landmines is data integrity. A real-time system is only as good as the information it's fed.

The old saying "garbage in, garbage out" has never been more true. A single missed scan or incorrect entry can create a ripple effect, causing discrepancies that make your team lose faith in the whole system.

To keep your data clean and your system trustworthy, watch out for these common issues:

- Poor Data Entry and Process Discipline: If your team isn’t scanning every single item as it comes in, moves, and goes out, your accuracy will nosedive. Solution: Make training a top priority. Build scanning into the natural workflow so it becomes a habit, not a chore.

- Lack of Employee Buy-In: If your team views the new system as just one more task piled on their plate, they won't use it right. Solution: Explain the "why" behind the change. Show them how it makes their jobs easier by eliminating manual counts and the frustrating hunt for misplaced items.

- Failure to Integrate with Other Systems: An inventory system that doesn't communicate with your sales or accounting software creates data silos. This completely defeats the purpose of having real-time visibility. Solution: Choose a platform that connects seamlessly with your other business tools to create a single, reliable source of truth.

By getting ahead of these challenges, you can make sure your real-time inventory system delivers on its promise for years to come. Ultimately, this level of visibility strengthens your entire supply chain, making you more resilient when disruptions hit. This ability lets businesses spot and react to problems faster, improve risk assessment, and operate with far less uncertainty. Learn more about how AI and sensor technology are boosting supply chain responsiveness.

Your Questions About Real-Time Inventory, Answered

Even when the benefits seem clear, switching to a live system brings up some practical questions. It's a big shift, after all. Here are a few of the most common things people ask when they're thinking about making the jump.

"Is this kind of thing only for big companies?"

Not anymore. While huge corporations rely on massive, complex systems, the core idea scales down beautifully. Smart apps and affordable tools have brought real-time tracking to small businesses and even households. Think managing your pantry, knowing what's in your tool shed, or keeping tabs on a valuable collection.

The trick is to find technology that fits your actual needs and budget. You don't need an industrial-grade system to know if you're out of olive oil.

"What’s the hardest part of switching over?"

Honestly, it's usually not the tech, it's the people. The biggest hurdle is the change in daily habits. A real-time system is only as good as the data you feed it, which means you need a rock-solid commitment to the new process. Every single item has to be scanned when it comes in and when it goes out. No exceptions.

Getting the whole team trained and bought into the new way of doing things is make-or-break. If usage is inconsistent, the system’s accuracy nose-dives, and you're right back where you started.

Real-time data gives you an incredibly sharp, up-to-the-minute picture of what's selling, where it's selling, and when. This granular detail is the fuel for smarter decisions across the board.

"How does this actually make forecasting better?"

When you pair this super-precise sales data with AI and machine learning, your forecasting models get scary-good. They can spot subtle trends a human would miss, perfectly account for seasonality, and even predict how a sale will affect stock levels with amazing accuracy. This is a huge leap from forecasts based on last week's or last month's numbers.

The result? You buy smarter and waste a whole lot less.

Ready to bring the power of real-time visibility to your home? Vorby uses smart technology to help you catalog, find, and manage everything you own with effortless precision. Stop searching and start knowing. Begin your free trial with Vorby today!